Table Of Content

This helps them commit to more accurate delivery plans and avoid the need for expedited freight. Comparing and choosing the best scenario in supply chain network design is a critical step that involves a careful evaluation of multiple factors. Gathering data to create a baseline and run different scenarios in supply chain network design is a foundational step that involves collecting, analyzing, and leveraging relevant information. Our research team is developing a methodology for assessing the environmental impact of pharmaceutical airfreight shipments based on the characteristics of the cargo, transport and containers. This methodology is incorporated in a network design model and applied to a comprehensive set of case studies, reflecting real-life cold-chain pharmaceutical logistics. Based on this analysis, companies can identify optimal logistics solutions that allow to decrease the emissions of cold chain pharmaceutical logistics.

What kinds of jobs can you get with Supply Chain Design skills?

ESG considerations in supply chain design encompass reducing carbon emissions, fostering sustainable sourcing, ensuring fair labor practices, and maintaining transparency and accountability in operations. Moreover, they are integrating ethical sourcing and labor practices to enhance the social sustainability of their supply chains. Sustainable supply chain network design is not only environmentally responsible but also aligns with evolving consumer expectations and can lead to cost savings and enhanced brand reputation eventually.

Product Links

The Distribution and Logistics Process determines how products are retrieved and transported from the warehouse to retailers. These products may be transported to retailers directly, or may first be moved to distribution facilities, which, in turn, transport products to retailers. This process includes the management of inventory retrieval, transportation, and final product delivery.

Green Supply Chain Management: What It Is and Why It Matters?

Tzafestas and Kapsiotis (1994) utilize a deterministic mathematical programming approach to optimize a supply chain, then use simulation techniques to analyze a numerical example of their optimization model. Moreover, this model develops material requirements and assignments for all products, while maximizing after-tax profits. Minimising warranty costs means the need to ship and store fewer parts and tools at service centres. For high-complexity products, greater customisation needs are customary and the design team determines the number of variants and the extent of each customisation. Due consideration must be given to the ability and feasibility of switching the supply chain type in the future if the need arises.

A cross-functional design process can reduce overall costs by 38% compared to the traditional linear approach. Thus, in order to prevent the negative impact of design on the supply chain, it is crucial that DfSC is opted for. Designers usually have little information about the ideal processes and materials for a product in regard to the proposed supply chain. But this information and more, such as the availability of different components, is already available with the logistics team.

What Are the Main Supply Chain Models?

Inventory holding costs are usually set to $0.50 per case per week, and stock out costs (costs for having a backlog of unfilled orders) are $1.00 per case per week. The task facing each player is a typical example of the stock management problem. Players must keep their inventory as low as possible while avoiding backlogs. To fulfill the incoming orders the inventory has to be depleted, so the players must place replenishment orders in order to adjust their inventory to the desired level.

Customer integration

It sets the stage for effective analysis, modeling, and strategic planning in the dynamic landscape of supply chain management. Service levels are a critical factor in supply chain network design, as they directly impact customer satisfaction and operational efficiency. Service levels encompass various aspects of delivering products or services, including on-time delivery, order accuracy, lead times, and responsiveness to customer demands.

Evaluate the effects of entering new markets or scaling back operations in existing ones. ESG, which stands for Environmental, Social, and Governance, is becoming a central consideration in supply chain network design. Businesses are increasingly recognizing the importance of aligning their supply chain strategies with ESG principles. This involves integrating environmentally responsible practices, considering social impact throughout the supply chain, and maintaining strong governance and ethical standards.

We investigate trade-offs between logistics costs and customer performance to design data-driven, customer-centric supply chains with multiple differentiated channel strategies. Supply chain design is the foundation of strategic supply chain planning, a key for organizations to create value. As supply chains become more end-customer-focused and global, their design becomes paramount as a competitive differentiator.

It is important to understand that the operational considerations for the location decisions are not enough for the supply chain location design. Operational considerations for choosing a location are still valid and useful, but they are mainly the measures of the operations costs from many different dimensions. The operational location design, for example will take into account of multiple factors on the supply side of operations as well as on the demand side of operations as shown in figure 8.

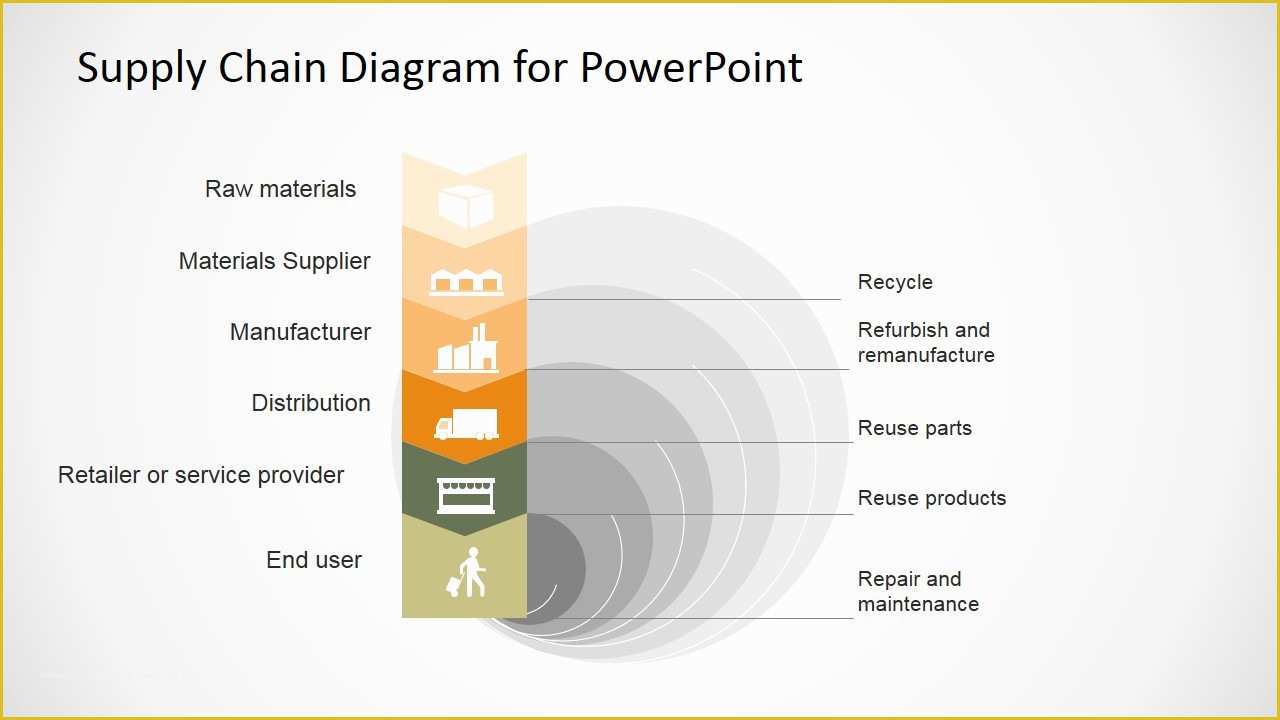

Supply chain network design involves strategically planning and optimizing a company’s supply chain structure. It includes decisions like choosing manufacturing locations and distribution centers and determining transportation routes and inventory levels. A supply chain starts with the ordering of raw materials or components from a supplier and ends with the delivery of a finished product or service to the end consumer. In supply chain management, every link in that chain may offer an opportunity to add value or reduce inefficiency.

The terms supply chain management (SCM) and business logistics management—or simply, logistics—are often used interchangeably. Most interesting, the patterns of behavior generated in the game are remarkably similar. Starting with the retailer, in the 20 weeks or so, inventories decline throughout the supply chain, and most players developed a backlog of unfilled orders (negative net inventory).

The total cost is a sum of average inventory holding and fixed (ordering, delivery, or set-up) costs. Finally, the performance of each heuristic is compared using a wide range of empirical experiments, and recommendations are made on the bases of solution quality and network structure. These processes interact with one another to produce an integrated supply chain. The design and management of these processes determine the extent to which the supply chain works as a unit to meet required performance objectives.

Supply Chain Management As A Strategic Differentiator - Forbes

Supply Chain Management As A Strategic Differentiator.

Posted: Wed, 08 Dec 2021 08:00:00 GMT [source]

You need to understand where your data comes from, and you need that data to drive your organization to better metrics. The authors observe that for their chosen example, the differences in total costs among the three scenarios are very close. The PDT must strive to build self-diagnostic features that can alert the operator of part or function failure in the product, especially for critical parts with a relatively high failure rate. This minimises the number of service calls as users can troubleshoot more effectively. The designers must also consider what alternate components could be used for manufacturing in the case of a shortage due to increased demand or diminished supply.

Freight costs and capital intensity are 10 to 15 percent lower, and customer delivery penalties and missed sales are 40 to 50 percent lower. IBP technology and process discipline can also make planners 10 to 20 percent more productive. We all know how critical supply chains are to the profitability of an organisation. An effective supply chain is possible only if it is designed well, taking into consideration all the elements in it. Expert supply chain professionals will design the function in such a way that customers are satisfied, and the company makes good profits. A good supply chain design also ensures better efficiency and lesser human interference resulting in lesser errors.

No comments:

Post a Comment